Baltibrew Yeast Capture: May I have your attenuation, please?

Back when we started our journey to wrangle some wild local microorganisms the biggest question we faced was not if we could capture yeast, but if we could capture yeast that would make beer.

Now we find ourselves at a crucial juncture. We need to measure the attenuative properties of our yeast isolates to determine if any of the samples can ferment the more complex sugars in a malt based wort.

Yeast is everywhere in nature, living in places like flowers, fruit, and tree bark. It grows by converting sugars into the energy it needs to multiply, producing ethanol as one of its coveted byproducts. All yeast can consume simple sugars like sucrose, glucose, and fructose.

Over the centuries many cultures developed rich traditions of fermented food and beverage. Before humans discovered the organisms responsible and assigned them names, people had already modified these lifeforms by reusing material from pleasing results. Brewers yeast, with its ability to ferment the maltose that makes up the majority of wort sugars, has been under heavy selection pressure throughout the course of human history.

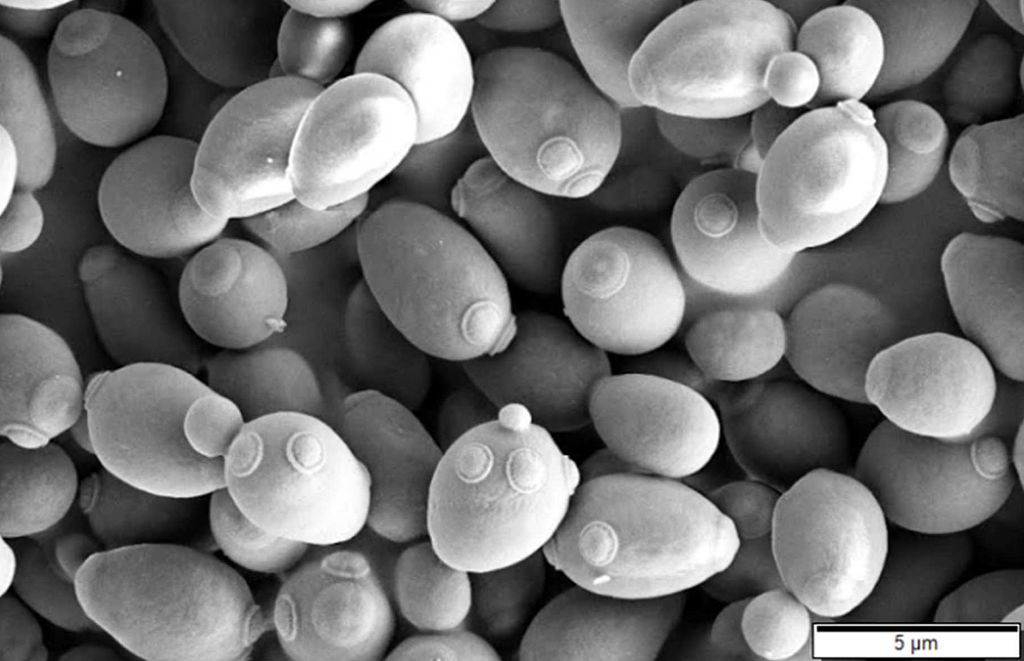

Saccharomyces cerevisiae, SEM image

The packs of dried and liquid yeast available to modern homebrewers are the culmination of years of brewing study and science. We are fortunate to be able to choose from a variety of proven yeast strains (and other organisms) when crafting our recipes.

The beers produced from this panel would have no such advantage.

Our project began in April when we prepared and distributed capture kits to our members.

In June, we triaged the results and jumped into the lab to plate and examine the captured organisms.

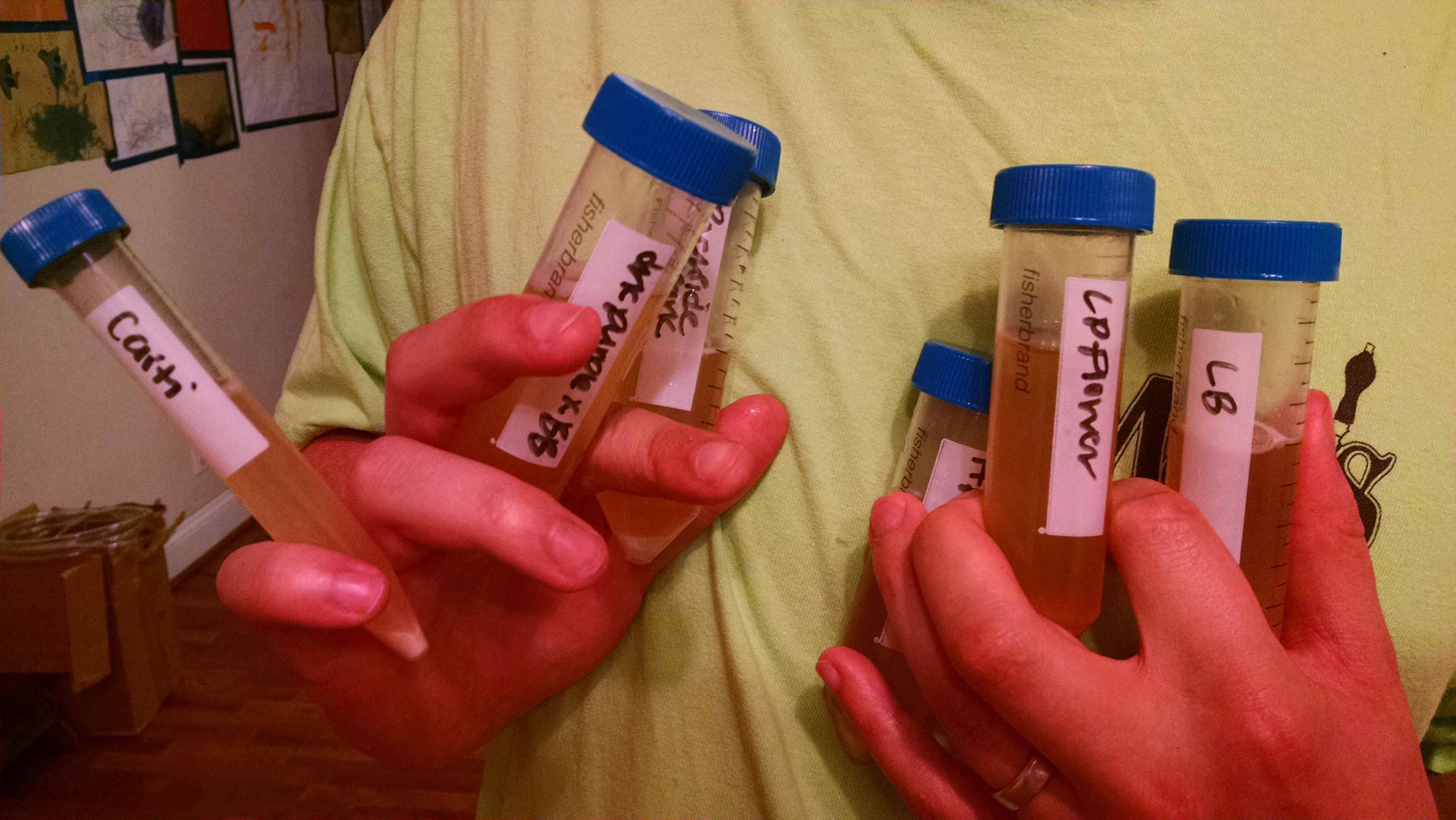

Baltibrewer Becky set to work this July, isolating and culturing up quantities of 6 strains of budding yeast. We decided the quickest way to find out what we had was conduct to a survey of 1 quart samples. The finished fermentations would be checked for specific gravity and pH drops. If any results were pleasing we’d bottle a 12 ounce sample. Yeast cakes would be saved for future use in larger batches.

Becky stepped up the cultures in the lab over the course of a few weeks and tested the samples for purity. On August 9th we met up with our yeast for a brewday!

Our yeast isolates!

For simplicity, we used Briess Light Dry Malt Extract and distilled water for our wort. We added a single charge of UK Sovereign hops for a bittering addition at 30 minutes.

| Original Gravity (Brix) | IBU | pH |

| 1.051 (13.2) | 20 | 5.26 |

While the wort chilled we sanitized jars and airlocks. Given the lack of headspace in our tiny fermenters we added a few drops of Ferm-Cap-S as we portioned the wort 7 ways (one extra jar for a US-05 control). We pitched our samples and to our pleasure within a day or two we were off to the races!

It begins!

Some jars showed more vigorous activity than others. We observed action in the airlocks of most. Given the homemade nature of our airlock fixture it was certainly possible our seals were not perfect. We decide to wait at least 2 weeks before checking the results. On August 29th, we gathered to investigate.

Getting down to the business of bottling.

We processed the beers one at time. A single jar was briefly opened and a sanitized pipette used to remove liquid for a Brix reading. After we assed attenuation, we moved on to a quick smell evaluation. Any interesting results were bottled and the finished pH noted. The rest of the sample would be transferred a smaller container and stored cold.

It was time! What would we find!

To our amazement, 5 of 6 samples showed a significant drop in gravity and pH! The threat of commercial contamination loomed in our heads as we recorded tasting notes from the uncarbonated beer.

To our pallets the cultures produced distinct flavor profiles in the fermented products, some quite notable! Between the variety of results, the different levels of activity and flocculation, and the fact that one culture did not attenuate well at all, we’re very hopeful these fermented beers represent true isolates from wild captures and our coolship barrels!

| Sample | Final Gravity (Brix) |

pH | Apparent Attenuation |

ABV | Notes |

| US-05 | 1.012 (6.6) | 4.07 | 76.4% | 5.25% | Did not save the yeast cake, tasted like a simple beer consistent with US-05 |

| Caiti | 1.013 (6.8) | 4.42 | 75.1% | 5.17% | Pleasing phenolic/spicy aroma, malty sweet taste |

| Riverside Park | 1.015 (7.5) | 4.43 | 70.9% | 4.88% | Fruity aroma, clean flavor profile with low esters |

| Kwanzan Cherry |

1.015 (7.5) | 4.40 | 70.9% | 4.88% | Pleasing but more assertive phenolic/spicy aroma, mild phenols on the front, with a mild dry/tannin finish |

| Little Barrel | 1.031 (11.2) | 4.69 | 40.0% | 2.80% | Did not bottle, smelled like baby diapers |

| Big Barrel (Dark Purple) |

1.016 (7.8) | 4.42 | 69.0% | 4.76% | Malty sweet aroma with phenols, sweet estery taste with more noticeable body |

| Big Barrel (Light Purple) |

1.014 (7.2) | 4.40 | 72.7% | 5.01% | Cinnamon/earthy spice aroma, sweet and dry taste with a peculiar spicy phenol during the finish |

We buzzed with excitement as we cleaned, dreaming of things we could do with the saved samples! But as we looked to the future, we also reflected on the road to this point. Capturing this many strains of yeast that could complete a fermentation was somewhat unexpected. How did we end up here?

Was our capture medium with its low OG, IBU, and pH a sufficient filter for the small amount of malt friendly yeast to take hold? Did the large number of initial captures followed by aggressive triage of moldy and failed samples set us up for a better success rate once we got into the lab? Were our expectations set too low to begin with? We’ll continue to reflect on the project as we wait to taste the carbonated samples at our next meeting.

With fall on the horizon we are eager to continue our quest to make beers with native strains of Baltimore yeast. Cheers and happy homebrewing!

A big milestone in our project: bottled beer and saved yeast from successful fermentations.